Sandy Ridge Kaolin Project – JORC Inferred Resource

Media Release

Key points:

- Tellus is pleased to announce the receipt of a JORC compliant inferred resource estimate for its Sandy Ridge Kaolin Project, Western Australia

- Tellus’ 100% owned 59km2 Sandy Ridge tenement is within an area of known thick kaolin (clay) occurrences

- The inferred mineral estimate is 41 million tonnes kaolinised granite, with an inferred ceramic grade resource of 7.9 million tonnes of kaolinised granite

- Kaolin is an industrial mineral used in paints, paper coatings, polymer industries, and ceramics

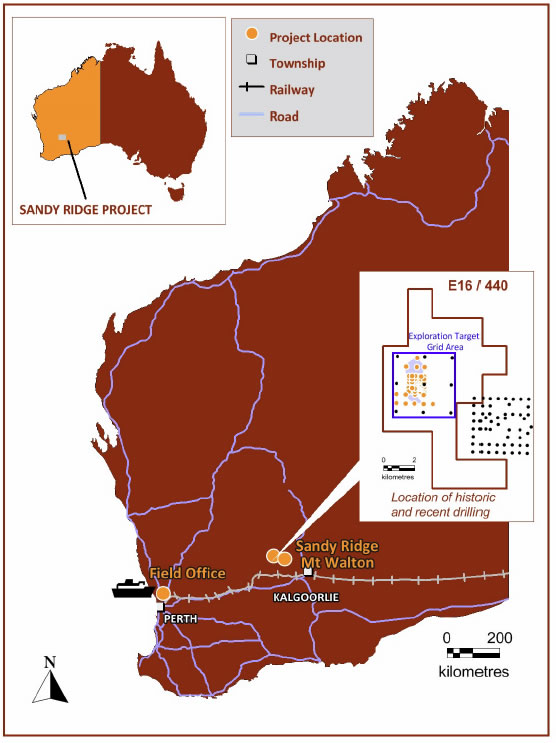

Tellus Holdings Ltd (Tellus) is pleased to announce a JORC compliant inferred mineral resource estimate for its Western Australian (WA) Sandy Ridge Kaolin Project. Tellus’ 100% owned E16/440 tenement is 140km north-west of Kalgoorlie and covers an area of 59.3 square kilometres (Figure 1). The Sandy Ridge resource represents a continuous, well-defined zone of high quality kaolinite.

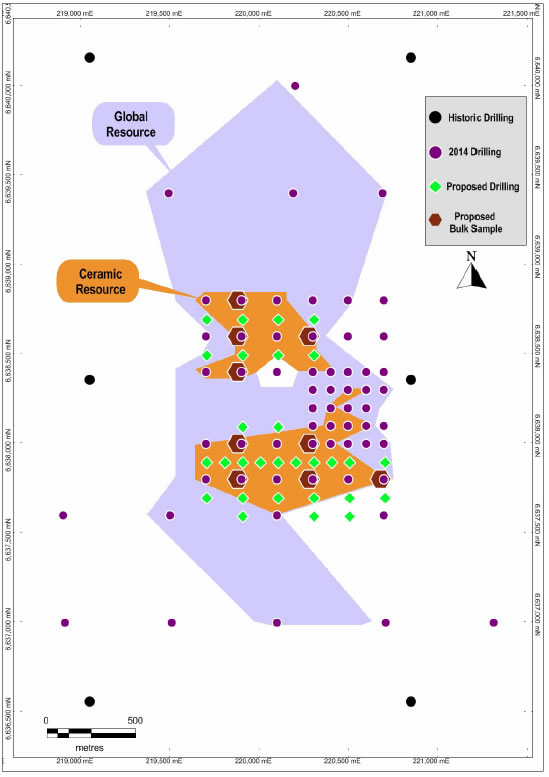

Tellus completed an air core drilling program in February 2014 with 1864 metres drilled. Drilling confirmed the presence of mineralisation over a strike length of 3050 metres. Portions of the deposit remain open and potential exists to expand the resource along strike in all directions.

Kaolin samples were sent to leading minerals assaying laboratory Nagrom for XRF analysis and First Test Minerals (UK) for brightness and other kaolinite specific testing. Resource estimates were determined by Terra Search Pty Ltd with provision of cut off levels and technical advice on kaolinite contributed by Engineering and Project Management Services (EPMS).

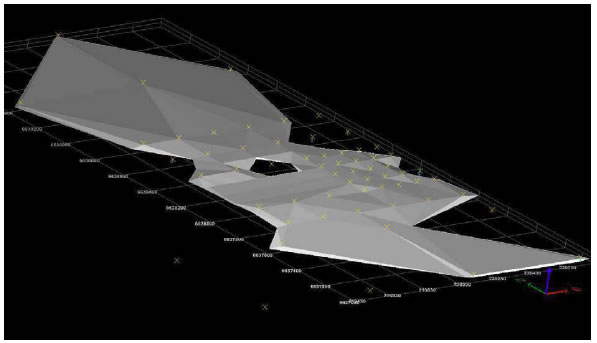

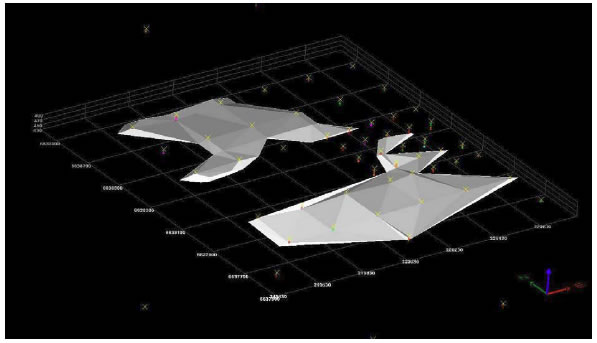

Two kaolinite envelopes were developed for assorted industry applications. The ‘Global Model’ was created with an 80% ISO brightness and 30% yield cut off (Table 1). The ‘Ceramic Model’ applied a 30% yield cut off and maximum value of 0.7% Fe2O3, 0.5% TiO2, and 2% K2O (Table 2). A conservative bulk density of 1.6 t/m3 was employed based on test work from similar deposits.

Table 1: Kaolinite Resource (cut off yield >30%, ISO brightness >80%)

| Mineralisation Envelope/class | Million Tonnes | Yield % (-45 micron) | ISO Brightness % | Fe2O3 % | K20 % | TiO2 % |

|---|---|---|---|---|---|---|

| Global Inferred | 41.3 | 40.38 | 83.42 | 0.75 | 0.71 | 0.41 |

Table 2: Ceramic Resource (cut off yield >30%, Fe2O3 <0.7%, K2O <2%, TiO2 <0.5%)

| Mineralisation Envelope/class | Million Tonnes | Yield % (-45 micron) | ISO Brightness % | Fe2O3 % | K20 % | TiO2 % |

|---|---|---|---|---|---|---|

| Global Inferred | 16.5 | 42.42 | 84.61 | 0.57 | 0.63 | 0.35 |

| Ceramic Inferred | 7.9 | 43.46 | 85.08 | 0.49 | 0.50 | 0.34 |

The initial exploration target for Sandy Ridge (April 2013) has been updated to reflect the information gained during 2014 drilling. The initial estimate is still valid over the entire area (Figure 1) although the average thickness has decreased. The updated exploration target of 179 to 333 million tonnes is considered a more accurate target (Table 3).

Table 3: Exploration Target for Sandy Ridge May 2014

| Class | Kaolinite Horizon | Kaolinite thickness (m) | Grid area (km2) | Estimated volume (km3) | Bulk Density t/m3 | Million Tonnes |

|---|---|---|---|---|---|---|

| Exploration Target* | Minimum thickness | 7 | 16 | 0.112 | 1.6 | 179 |

| Average thickness | 13 | 16 | 0.208 | 1.6 | 333 |

*The term “target” should not be misunderstood nor misconstrued as an estimate of Mineral Resources and Reserves as defined by the JORC Code (2012), and therefore the term has not been used in this context. It is uncertain if further exploration or feasibility study will result in the determination of a Mineral Resources or Mining Reserve.

Analysis results indicate Sandy Ridge’s kaolin quality is potentially suitable for a range of end uses including paint filler, high quality tableware ceramics, continuous filament glass fibre, and paper filler. Planned further testing will confirm product specifications.

“Tellus is in discussion with potential customers to further test the kaolin to meet their requirements” Tellus Managing Director Duncan van der Merwe said.

“A bulk sampling program planned for Q3/Q4 2014 will provide samples for pilot plant test work in order to determine the most appropriate product mix.”

Further infill drilling is planned for 2014 to confirm mineralisation continuity across the deposit.

Competent person statement

The information in this report that relates to Mineral Resources is based on information compiled by Terra Search Pty Ltd. Mr Jenkins is Principal Geologist of Terra Search and a Member of the Australian Institute of Geoscientists. Mr Jenkins has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration, and to the activity that he has undertaken to qualify as a Competent Person as defined in the 2012 Edition of the Australasian Code for the Reporting of Mineral Resources and Ore Reserves. The Mineral Resource estimate complies with recommendations in the Australian Code for Reporting of Mineral Resources and Ore Reserves (2012) by the Joint Ore Reserves Committee (JORC).

About Tellus Holdings

Tellus Holdings Ltd (“Tellus”) is an Australian exploration company in mine evaluation stage with an attractive portfolio of rock salt and kaolin deposits. Tellus’ flagship projects are a proposed underground rock salt mine in the Northern Territory and a proposed kaolin mine in Western Australia. Tellus is the parent of a group of companies that plans to be involved in mine building, processing and the sale of industrial and edible salts, associated salt minerals and kaolin. Proposed complementary businesses include the safe storage in voids created by mining as is done in countries like the UK, EU, USA and Canada.

For further information on Tellus:

Visit: www.tellusholdings.com.au or contact:

Duncan van der Merwe

Managing Director

Tel: +61 (0)2 9241-7678

Jane Munday

Michels Warren Munday

Mob: +61 (0)427 880 083

Appendix

Section 1 Sampling Techniques and Data

| Criteria | Commentary |

|---|---|

| Sampling techniques | Air core samples were collected at 1m intervals from a rig mounted riffle or cone splitter. 75% of each metre sample was collected in a 900x600mm green plastic bag, and the remaining 25% (split sample) was collected in a 610x405mm green plastic bag. The split samples were collected directly from the cyclone because the samples for assay were to be collected in plastic rather than calico bags (% moisture needs to be measured, and fine dust (red) can get into calico). |

| Drilling techniques | Air Core drilling using a Mantis 100 drill rig with an NQ Air Core sand bit. Roughly 3m from the surface a 2-4m silcrete band was intersected which was too hard for the sand bit. As a result, a hammer bit was used and no sample was returned. |

| Drill sample recovery | Actual recoveries from Air Core drilling were not measured, however Terra Search reported to Tellus that recovery of drill samples from all drilling campaigns were of an acceptable standard. |

| Logging | Chip tray samples were taken along with usual logging and the chip tray samples were non-sieved and dry. All holes were field logged by 1m intervals by a Terra Search geologist for geological characteristics. |

| Sub-sampling techniques and sample preparation | All sampling procedures for the Air Core drilling have been reviewed by Tellus and EPMS and are considered to be of a high standard. Air Core drilling procedure was 1m samples split using a rig mounted cone splitter and collected in marked plastic bags. 1-2kg was collected in small green plastic bags and 4-6kg was collected in large green plastic bags. All samples were dry. 1-2kg samples totalling 776m were brought back to Perth and sorted into composites. 140 composite samples were made up from the 776 metres with a maximum of 3 composites per drill hole and a maximum interval of 12m. The composites were made using a spear making sure equal amounts were collected from each metre, thus giving a homogeneous of each metre amount in the composites. 110 were sent to Nagrom for basic assay, 10 duplicates were sent to Nagrom for QAQC. 20 duplicates were sent to First Test Minerals for QAQC and brightness testing. 120 samples (Original 110 and the 10 Nagrom duplicates) were sent to FTM for brightness testing. |

| Quality of assay data and laboratory tests | Analysis for Yield, Brightness, Yellowness, SiO2, Al2O3, Fe2O3, TiO2, CaO, MgO, K2O, Na2O, P2O5, Mn3O4, V2O5, Cr2O3, BaO, ZrO2, ZnO, SrO and LOI, was completed using XRF. The majority of duplicates are within tolerance of the original assay and without bias. Terra Search reviewed internal QAQC reports and EPMS analysis and confirms that all assay data used has passed standard industry quality assurance/quality control procedures. |

| Verification of sampling and assaying | No verification sampling or drilling has been carried out. |

| Location of data points | All drill holes used in the resource estimate have been accurately surveyed using Garmin GPSMAP 62s equipment (+/-5m accuracy) by the geologist on site. No down hole surveys have been conducted however all holes are drilled vertically. |

| Data spacing and distribution | 24 holes were drilled in a 1km square at 100m spacing. 24 holes were drilled over a 1km grid at 200m spacing. 13 holes were drilled over a 3km grid at roughly 600m spacing. The drill spacing was considered adequate to establish both geological and grade continuity for definition of Inferred Mineral Resource. Samples were composited to 3-11m for analysis. |

| Orientation of data in relation to geological structure | The orientation of the drilling is approximately perpendicular to the strike and dip of the mineralisation and the risk of sample bias is considered to be low. |

| Sample security | All samples were under supervision from the rig to the laboratory. All residual sample material is stored securely in sealed bags. |

| Audits or reviews | Terra Search has reviewed QAQC results and found these to be acceptable. |

Section 2 Reporting of Exploration Results

| Criteria | Commentary |

|---|---|

| Mineral tenement and land tenure status | Tellus Holdings Ltd holds granted tenement E16/440 in Western Australia, covering and area of 59km2 |

| Exploration done by other parties | Historic drillhole data is available from a study by Alan Tingay & Associates (1995) which consists of 63 Rotary Air Blast (RAB) drill holes that were completed in July 1995. Of this previous drilling; 10 drill holes are located within Tellus’ E16/440 tenement boundary. |

| Geology | In the vicinity of the Sandy Ridge Kaolin Project area, Archaean rock of the Yilgarn Granites Supersuite is the likely parent material for the kaolin. Here, deep weathering of the feldspathic and ferromagnesian minerals within the metamorphosed granitic has resulted in the formation of kaolinite. Flanking these rocks are similarly aged metamorphosed mafic dominant granite-greenstones of the Youanmi Terrane – Southern Cross Domain. Also present within the area are sedimentary siliciclastic rock, including metamorphosed sandstone, siltstone, shale and chert. |

| Drill hole Information | 61 air core drillholes were completed with a total of 1864m drilled. All holes were drilled vertically. Intersected kaolin thickness ranged from 3-26m. |

| Data aggregation methods | ‘Global Model’ used a 80% and 30% cut off for brightness and yield respectively ‘Ceramic Model’ used a 30% yield cut off and a maximum value of 0.7% Fe2O3, 0.5% TiO2 and 2% K2O.Cut offs were supplied by Engineering and Project Management Services (EPMS) based on standard industry specs for kaolinite. Samples within the wireframes were composited to 3-11m intervals based on visually contiguous down-hole intervals. The intervals were selected by Terra Search’s geologist, with guidance by EPMS. No high-grade cuts were applied. |

| Relationship between mineralisation widths and intercept lengths | All drill holes are vertical. The orientation of the drilling is approximately perpendicular to the strike and dip of the mineralisation. |

| Diagrams | Refer to figures 1-4 |

| Balanced reporting | The reporting is considered to be balanced. |

| Other substantive exploration data | Nothing material to report. |

| Further work | Terra Search recommends continuing the current QAQC practices with close monitoring and reviewing of results. Terra Search recommends a bulk sampling or suitable drilling program to conduct bulk density sampling across the extent of the deposit area. Terra Search recommends infill drilling between sections, with a 50m -100m spaced program in the two high grade zones. |

Estimation and Reporting of Mineral Resources

| Criteria | Commentary |

|---|---|

| Database integrity | Terra Search performed initial database audits in Mine Map. |

| Site visits | A site visit has not been undertaken by the competent person. The drilling program was supervised in-field by Terra Search Project Geologist, under overall supervision of the competent person. |

| Geological interpretation | Geological drilling has confirmed a generally continuous kaolinite unit within E16/440. Two discrete high grade zones (>30 and >83 yield and brightness respectively) have been confirmed. |

| Dimensions | The Sandy Ridge deposit extends for approximately 3.1km in a NS direction and is open in all directions. The kaolinite extends from near-surface to 38m below the surface. |

| Estimation and modeling techniques | The ‘Global’ Sandy Ridge deposit was domained based on kaolinite occurrence with a 30% yield and 80% brightness cut off. All domains were applied as hard boundaries in the estimate. Statistical analysis was carried out on data from each of the two domains. High grade cuts were not applied as low co-efficients of variation (CV) were observed. The block model used a parent block size of 50m NS by 50m EW by 2m vertical. The block size was selected on the basis of approximately 50% of the nearest drill hole spacing. The dimensions in other directions were selected to provide sufficient resolution to the block model in the across-strike and down-dip direction. |

| Moisture | Moisture content was measured at the First Test Minerals laboratory giving a range of 7-13% moisture. Tonnage estimates are based on the assumed bulk density that is deemed to be a dry weight. |

| Cut-off parameters | Overall the kaolinite unit displays good continuity. Two models were created for different industry applications: ‘Global Model’ used a 80% and 30% cut off for brightness and yield respectively ‘Ceramic Model’ used a 30% yield cut off and a maximum value of 0.7% Fe2O3, 0.5% TiO2 and 2% K2O. Cut offs were supplied by Engineering and Project Management Services (EPMS) based on standard industry specs for kaolinite. Grade-tonnage plots were produced to allow further studies. |

| Mining factors or assumptions | No Assumptions have been made and the model is undiluted at this time. |

| Metallurgical factors or assumptions | No assumptions have been made regarding metallurgy. |

| Environmental factors or assumptions | A mining concept study has been completed by EPMS Pty Ltd that outlines the mining methodology, mining equipment, site layout, and outlines the storage of waste rock in waste rock dumps adjacent to the resource. |

| Bulk density | A bulk density of 1.6 was used for the kaolinite unit, which is based on conservative estimations from previous studies (AMMG, 2011) |

| Classification | Mineral Resources were classified in accordance with the Australasian Code for the Reporting of Identified Mineral Resources and Ore Reserves (JORC, 2012). The classification of the Mineral Resource was completed by David Jenkins of Terra Search. The reasonable drill hole spacing and demonstrated continuity of mineralisation warranted a classification of Inferred Mineral Resource. |

| Audits or reviews | Internal audits have been completed by Terra Search and the Mineral Resource estimate was considered to be satisfactory. |